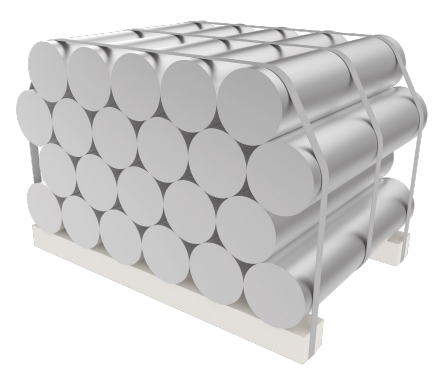

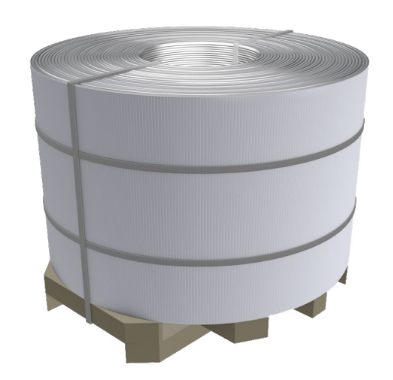

Production

We provide an end-to-end solution, ranging from high-quality extrusion to well-engineered products

Recycle

We work toward achieving a secured and better future. Our aluminum products can easily be recycled

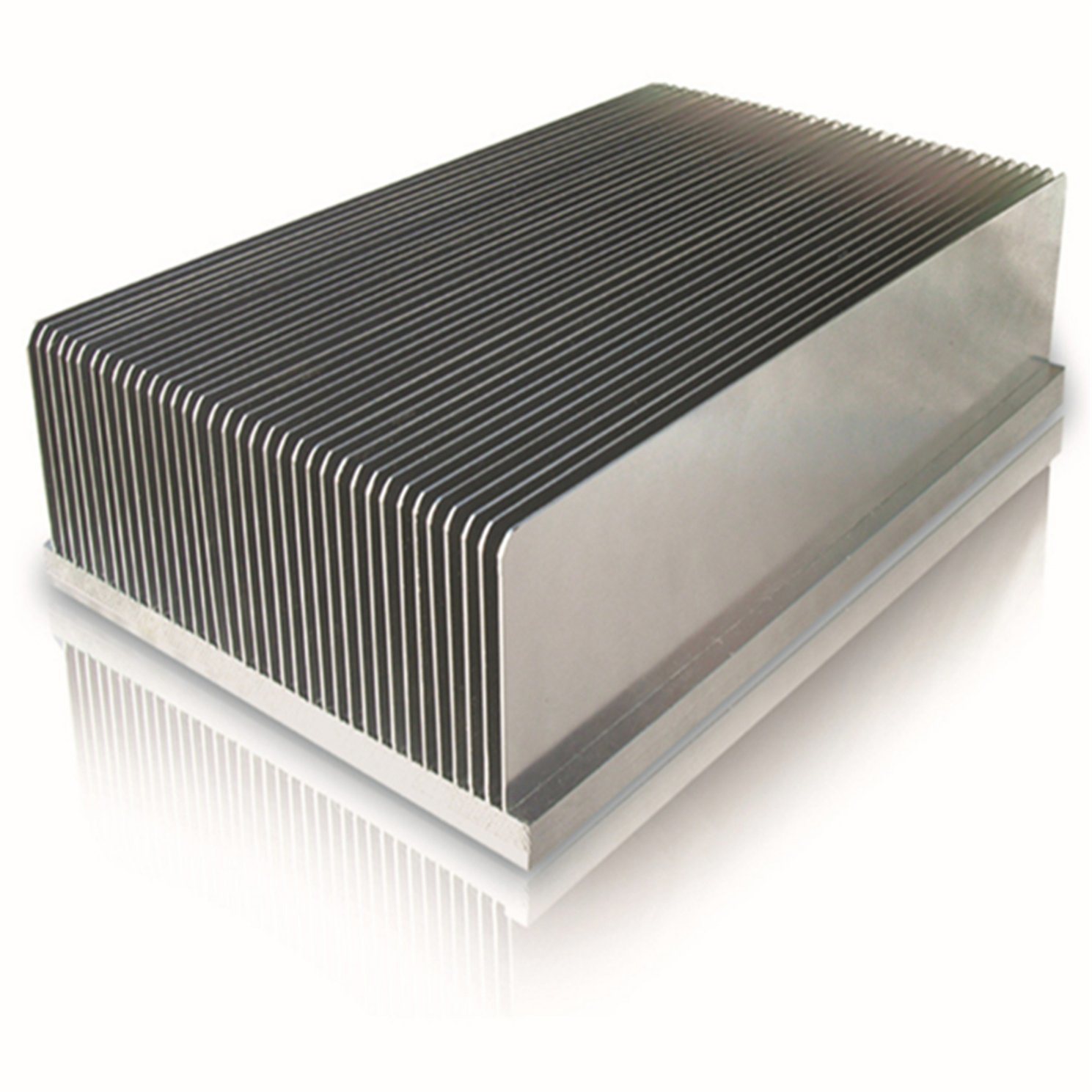

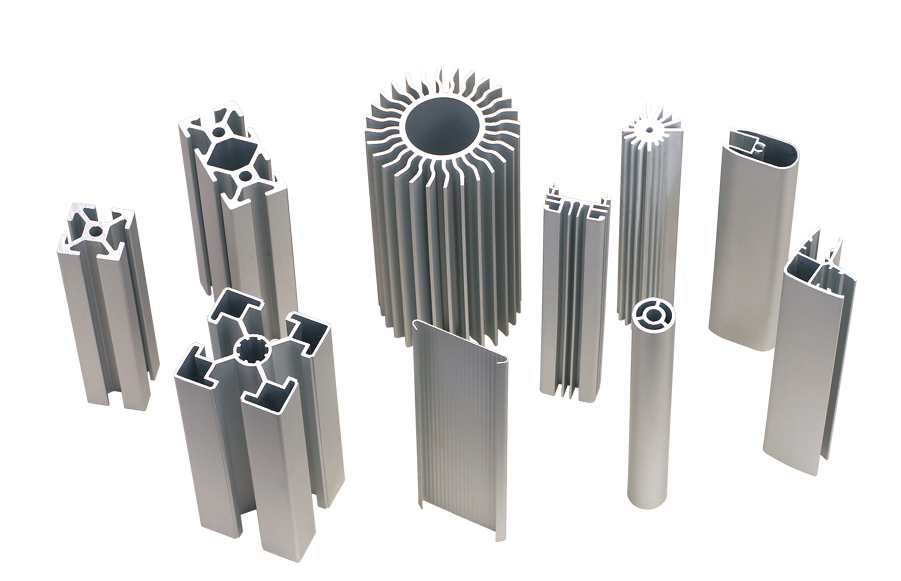

Finished product

You can expect a uniquely designed premium-quality product that offers high functionality

About Us

Based in Florida, METAL MAGIC FABRICATION LLC is a leading aluminum manufacturer whose goods are widely accepted across industries, including minerals, chemicals, architectural, aviation, electronics, transportation, and machinery, among others. We have established ourselves as an undisputed industry leader due to our dedication to cutting-edge manufacturing methods, R&D, quality assurance, and continual training for our staff. Our company's aluminum production facilities cover a wide range of activities, including bauxite mining, alumina refining, coal mining, captive power plants, aluminum smelting, downstream rolling, extrusions, and foil production.

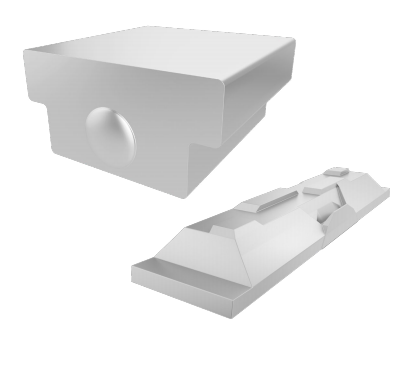

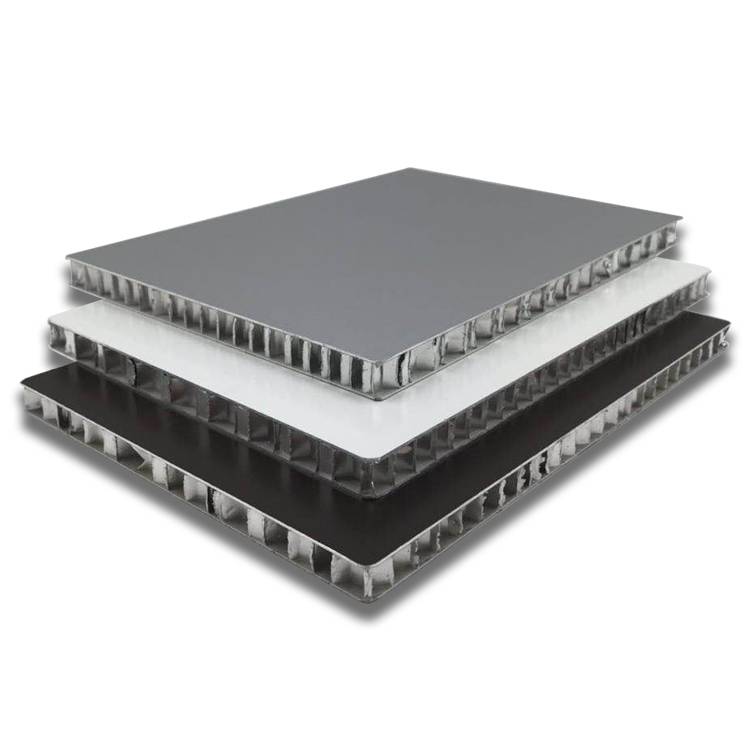

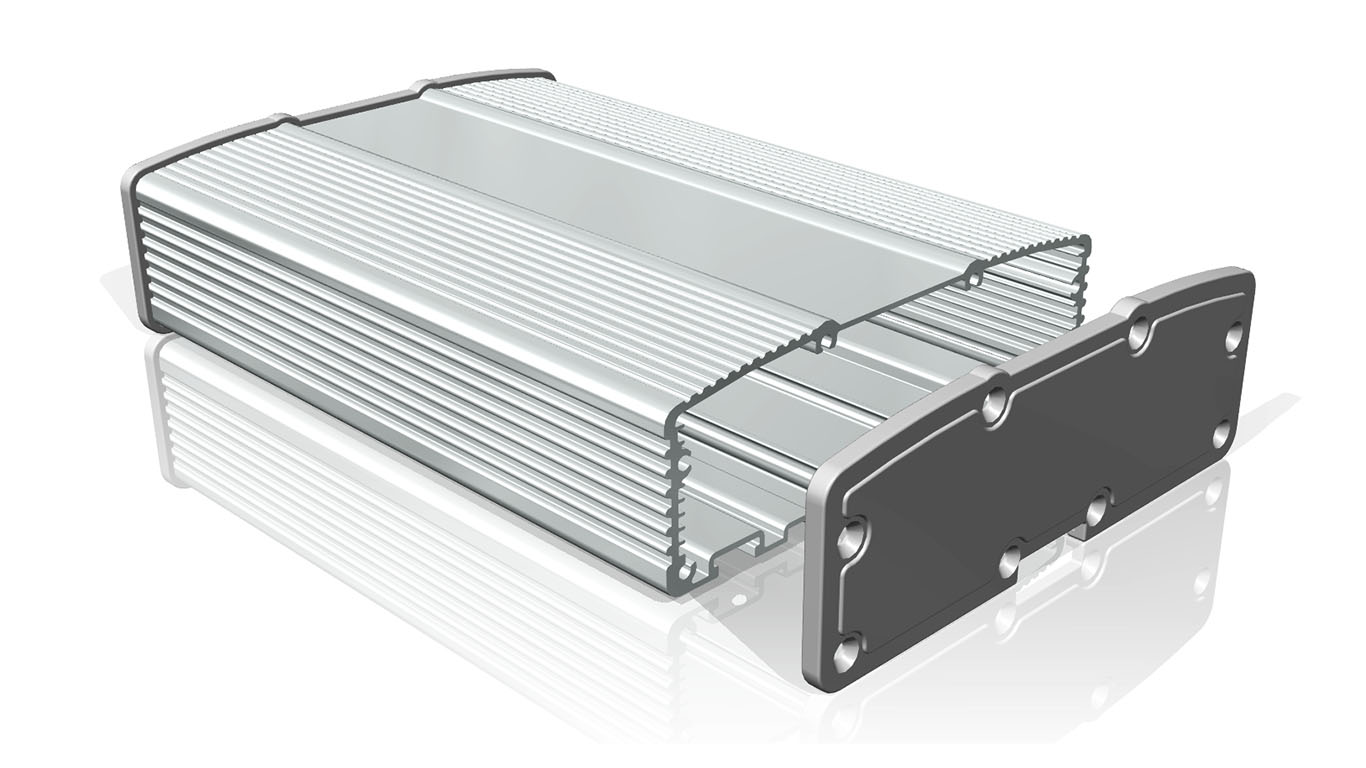

Major products manufactured in our production unit are aluminum wire, cylindrical and flat-shaped ingots, elongated dome frame, foil and packaging, honeycomb aluminum panel, junction box, primary aluminum, primary casting alloys, raw aluminum, aluminum pipe, aluminum profile for tile, aluminum water tank, aluminum welding wire, aluminum alloy and case, aluminum utensils and more. These products are made using premium raw material with cutting-edge technology, per the set industry standards, ensuring precision, optimum performance and customer satisfaction. Our products have a good reputation in the industry for dependability, longevity, and corrosion resistance. The usage of smart technology helps us bring down water and energy consumption, taking us one step closer to our vision of sustainability and going green.

We put customers’ interest first and have a very capable and professional team who is dedicated to work with them to achieve their goals and keep exceeding their expectations. We have a fully functional service system and production chain. The processing tools used in the manufacturing chain include cutting machines, bending machines, punches, water jet cutters, polishers, shearing machine, drawing tables, and others. Strict manufacturing inspections are performed on every product. High-quality steel goods and the greatest customer service are our top priorities. For all you aluminum-related needs, you can visit www.alumagicfab.com or call us at 689-205-8414.

Know More

How aluminum Is Produced

BAUXITE MINING

This is the very first step in aluminum production. This aluminum-rich rock contains the metal in the form of hydro-oxide. The tropical belt is home to the majority of the world's bauxite reserves—about 90%.

ALUMINA PRODUCTION

With a minimal amount of water, bauxite is crushed, dried, and processed in mills. The thick material that results is collected in a vessel and cooked with steam to largely separate the silicon present in the bauxites.

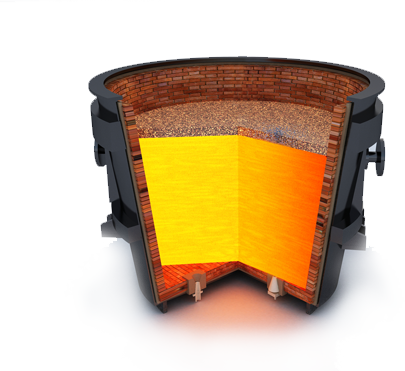

ALUMINUM ELECTROLYSIS

In baths filled with molten cryolite at the aluminum factory, alumina is poured at a temperature of 950 ⁰S. A 400 kA or greater electric current is run through the solution, breaking the connection between the oxygen and aluminum atoms, causing the metal to condense in liquid form at the bottom of the bath.

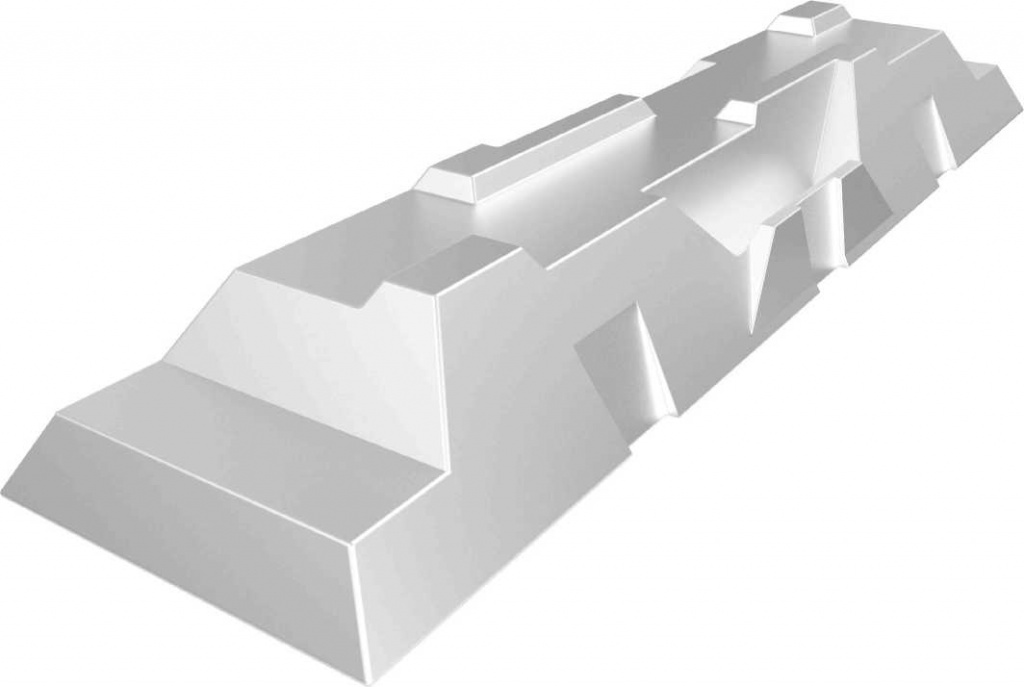

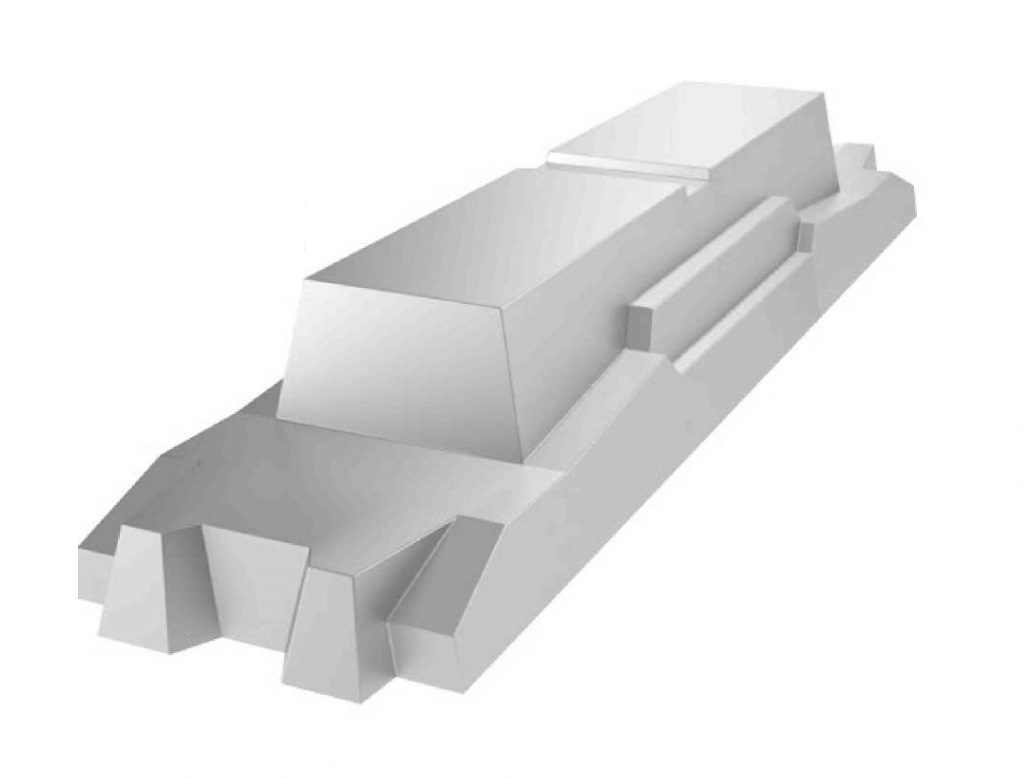

PRIMARY ALUMINUM

The next step involves primary aluminum being cast into ingots and delivered to consumers. It may also be further used for producing aluminum alloys for different purposes.

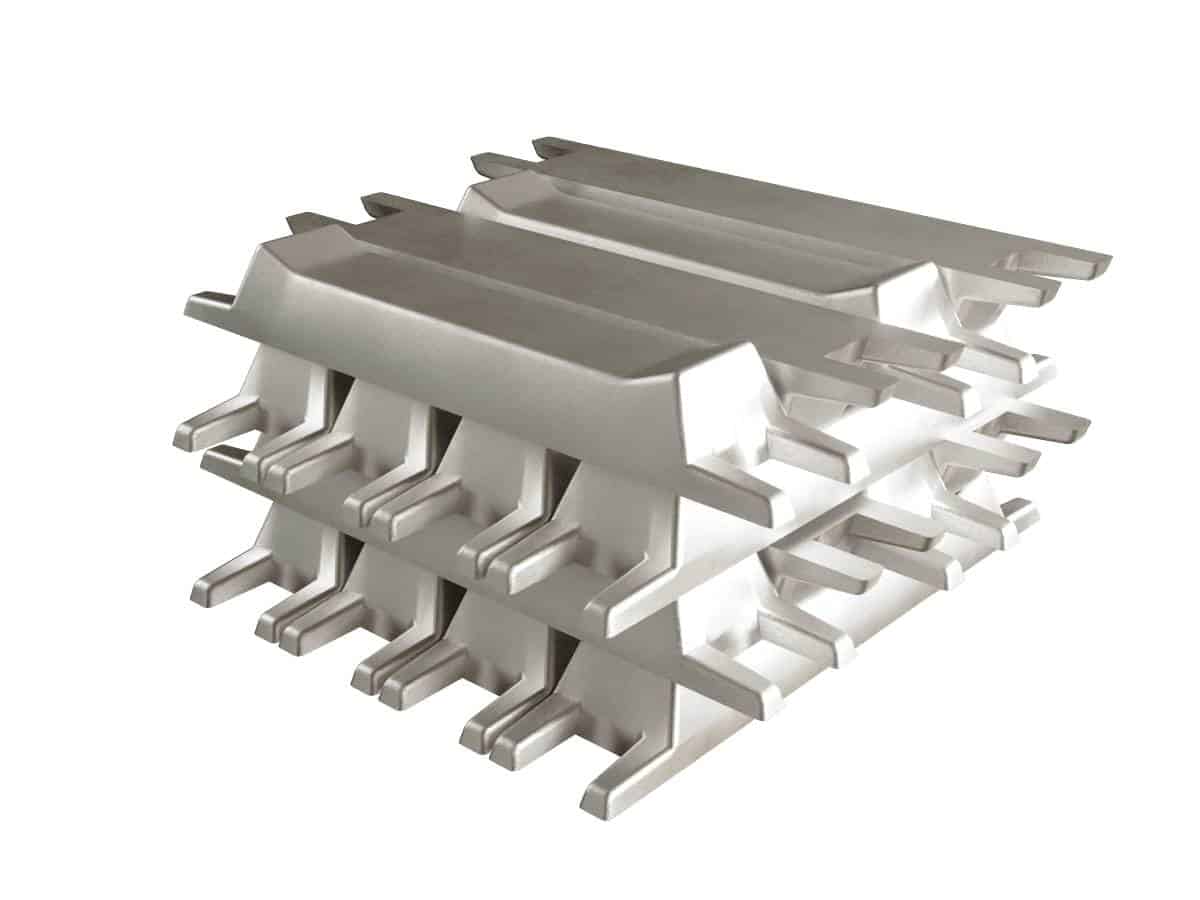

ALUMINUM ALLOYS

By pouring metal into molds, cast aluminum alloys are used to create finished products. Simultaneously, other additives like silicon, copper, and magnesium are added to the alloy in order to give it the desired qualities. A few examples of the products made from such alloys are wheels or engine components for automobiles and aircraft.

ALUMINUM PROCESSING

Since aluminum does not corrode, unlike iron, goods made from it may be smelted and the resulting metal utilized indefinitely. Just 5% of the energy needed to produce aluminum is used in the processing of the metal.